Description

Montana Collection: 422 Natural Maple

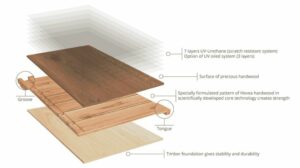

What is Engineered Hardwood?- Both solid hardwood planks and engineered planks are made from 100% real wood. And both types are capable of delivering a beautiful and durable floor. It is important, however, to learn about the differences between the two, like construction, stability, installation and, of course, cost. Once you get a good grasp of all these factors, your ultimate choice will be easier—and more accurate.

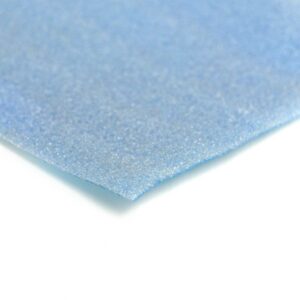

Stability: The good thing about the solid vs. engineered analysis is that both forms will provide durability and toughness in active homes. Solid wood flooring is inherently durable but must be permanently nailed or glued to the subfloor. Because of expansion and contraction issues, solid hardwood floors are more prone to shrinking or expanding based on humidity levels which can change drastically here in the Arizona Deserts. Engineered floors can have greater dimensional stability in extreme temperatures, which provides slightly more resistance to buckling or rippling. How much durability your engineered wood will provide goes back to the core construction that you choose.

Installing Hardwood: Where are your new floors going inside the home? Solid hardwood will expand and contract with changes in temperature and moisture, so they are only recommended at or above ground level. Also, the installation method for solid hardwood takes some consideration. Solid hardwood flooring can be glued, nailed or stapled to a wood subfloor but must have the right amount of space for hardwood’s natural expansion and contraction. If the individual boards are too tight, the floor will buckle, and if they are too loose, then the gaps between the boards will get too wide during colder temperatures.

Gluing hardwood down in Phoenix can be a challenge since solid hardwood isn’t as “true” and uniform as engineered floor would likely be due of the nature of wood. So All Pro Floors recommends using a plywood subfloor and stapling hardwood when possible. Of course this adds cost and height so these are important design and budget factors to consider when choosing between engineered and solid floors

Installing Engineered: Engineered wood has enhanced installation options due to its unique construction that makes it less likely to buckle, gap or react to heat or temperature change. Floating, glue, staple, nail, you name it, the choice of installation is yours. Engineered wood can even be installed below and over radiant heat. This makes engineered wood a great fit for installing above, on or below ground level in your home.

Cost: Your budget will help determine a lot about the best hardwood for you. Generally speaking, engineered hardwood is less expensive than solid hardwood, but ultimately the quality and species of wood will be the biggest price determinants. Exotic solid hardwood species are certainly pricier than engineered hardwood.

Engineered Hardwood Styles

Just like real hardwood floors, engineered wood floors offer a broad selection of looks that can match any home. Discover how different species, textures, and finishes can give you a personalized, unique style.

Species and Colors

Whether you want the versatility of oak, the depth of birch, or the brightness of hickory, there’s a type of wood suited to you. You can also choose eco-friendly and renewable species like bamboo or cork.

Engineered wood showcases the beauty of natural grains and color variations. High color variation is making a big splash in the Scottsdale interior design world, and there’s no better way to attain that sought-after look than to achieve it naturally.

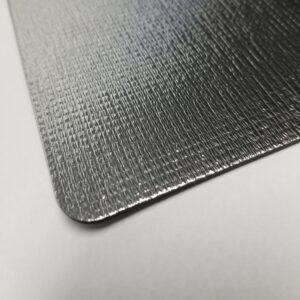

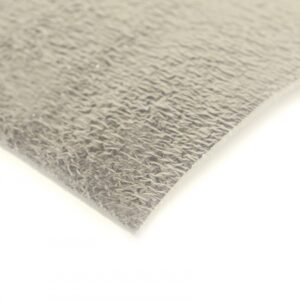

Textures

The authentic look of rustic textures is really popular right now, and engineered hardwood delivers on that front. Take your pick of hand-scraped, wire-brushed, or distressed planks to enhance your space.

And don’t worry about those intentional scratches getting messed up by the trials of everyday life. With a thick enough wear layer, your designer textures will remain intact and looking brand new.

Finishes

Most engineered wood comes pre-finished, which is great, because it saves you a step. However, you want to ensure you love the finish before purchasing any flooring.

Many designs are currently opting for a more subdued or matte finish, but you can still choose your desired finish.

Plank Size

Big things are happening with plank size. Literally! Planks are getting bigger and wider as homeowners lean toward cleaner lines and styles that will open up small spaces.

In addition to wide plank options, you can also choose mixed width planks. This style breaks up the sameness of your floor with differently sized planks. It’s like a surprise party for your floor!

Tongue and Groove

The tongue and groove design is the most common installation method for engineered hardwood. Insert the tongue of one plank into the groove of another to attach the planks. Planks can be nailed down, glued down, or even installed as a floating floor.

If you want to float tongue and groove planks, you will need to glue the planks together using T&G glue.

Interlocking

This installation method isn’t as common as the others, but it’s the most popular among DIY’ers. Simply insert the tongue of one plank into the groove of another, and lay the plank flat to snap them together.

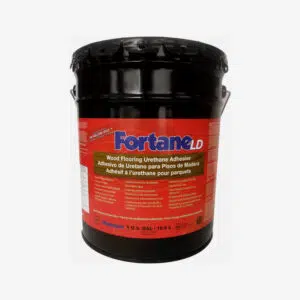

Glue Down

Glue down installation is a permanent solution, and it’s well-suited for high-traffic commercial areas where you really want to make sure your flooring is stable. This method is best left to the pros, or you and your floor are likely to be covered in glue that isn’t easily removed. Even all the Paint-thinner in Phoenix won’t help you!

Pros and Cons of Montana Collection Engineered Hardwood Flooring

What Are the Advantages of Montana Maple Engineered Hardwood?

- More affordable than solid wood: You get the high-quality visuals of real wood without that big price tag, and nobody will be able to tell the difference. Score!

- Every plank is unique: Since this is a real wood veneer, you’ll never find a repeating pattern or an unconvincing texture.

- Moisture resistance: Depending on the core of your flooring, your engineered wood could be moisture resistant or even 100% waterproof.

- Install it anywhere: High moisture resistance means you can install it in bathrooms, kitchens, laundry rooms, and even basements! No grade level of your home is off-limits.

- DIY-friendly: Some engineered hardwood is designed with click-lock or tongue-and-groove installation, and it floats above your subfloor. No nails or glue here!

What Are the Disadvantages of Engineered Hardwood?

- Not traditional hardwood: This is important to some people. No matter how great it looks, it’s not solid hardwood.

- Difficult to DIY: While some engineered hardwood offers a simple click-lock design, other styles might need to be nailed or glued down. That will take some more time and effort.

- Might not be able to refinish: Depending on what the manufacturer says, it might not be possible to refinish your engineered hardwood. While this cuts back on maintenance, you have less flexibility when it comes to redesigning.