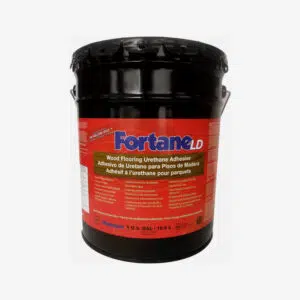

Description

SikaBond T25 Urethane Adhesive

Usage

SikaBond®-T25 may be used to bond all engineered, solid plank flat milled, solid shorts, bamboo, cork and parquet hardwood flooring designed by the manufacturer for glue down applications. This adhesive can also be used for many other bonding applications that are common for light commercial and residential applications including acoustic rubber underlayment systems.

SikaBond T25 Urethane Adhesive Advantages

- 125% Elongation

- Bonds up to 3/4″ solid and engineered wood

- Low odor

- Easy to trowel

- Excellent workability

- Fast curing

- Crack bridging

- Suitable for common types of wood floors

- Suitable for in-floor radiant heat installation

- Contains no water

- Tenacious bond

Packaging

5 gal. (18.93 L) unit

Color

Tan

Product Details

Sustainability / Certifications / Approvals

APPROVALS / STANDARDS

| LEED® EQc 4.1 (100 g/L limit) |

SCAQMD, Rule 1168 (100 g/L limit) |

BAAQMD, Reg. 8, Rule 51 (120 g/Llimit) |

| passes | passes | passes |

Application

Sag Flow

Consistency: Spreads easily, holds ridges after troweling

Ambient Air Temperature

Room temperature between 60°F (15°C) and 90°F (35°C). For ambient temperatures the standard construction rules are relevant. Follow all wood floor manufacturer’s acclimation and room temperature requirements.

Relative Air Humidity

Between 40% and 70% during installation is best for adhesive. See wood floor manufacturer for wood requirements.

Substrate Temperature

During laying and until SikaBond®-T25 has fully cured, substrate temperature should be greater than 60°F (15°C) and in case of radiant heating, less than 70°F (20°C). For substrate temperatures, the standard construction rules are relevant.

Substrate Moisture Content

For use as an adhesive only: SikaBond® T-25 is not affected by moisture or vapor transmission. For protection of the wood, follow the wood floor manufacturer’s requirements for subfloor moisture. If substrate is not acceptable, use SikaBond® T-25 at recommended coverage rate as All-in-One or Sika® MB. See Technical Data Sheet for proper instruction.

For use as an adhesive and moisture membrane: Concrete moisture vapor emission rate (MVER) may not exceed 12 lbs. per 1,000 sq.ft. (5,44 kg per 92,9 m2) per 24 hours, anhydrous calcium chloride test (ASTM F1869). Do not install when the relative humidity (RH) of the concrete slab exceeds 87% (ASTM F2170).

Curing Rate

Floor may accept light foot traffic after:

- at 45–50 SF/gal (P5 trowel): after 6–8 h

- at 30–35 SF/gal (SC+MB trowel): after 12 h

(depending on climatic conditions and adhesive layer thickness)

Floor can be sanded after 18 hours

Skin Time / Laying Time

~ 45-60 minutes at 73°F (23°C) and 50% RH

Visit Our Phoenix Showroom!