Description

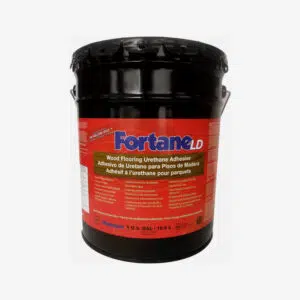

SikaBond T-21 Adhesive

SikaBond-T21Adhesive

SikaBond®-T21 is a one-component, low VOC, permanently elastic, super strong, very low permeability moisture-cure polyurethane adhesive, vapor retarding, crack bridging and sound reduction membrane all-in-one for full surface wood floor bonding.

Usage

Advantages

- 270 % elongation

- Bonds up to 3/4″ solid and engineered wood

- Extremely easy to trowel

- Unlimited subfloor moisture vapor protection

- No moisture testing required – a dry to touch substrate is the only requirement

- Crack bridging

- Low odor

- Excellent Green Grab

- Suitable for common types of wood flooring

- Creates sound reduction layer

- Especially good for problematic woods such as beech and bamboo

- Contains no water

- Eliminates sleepers and plywood over concrete and gypsum substrates

- Permanently elastic – allows planks to expand and contract without damage to the adhesive

- Tenacious bond

Packaging

4 gal. (15.14 L)

Color

Light Brown

Product Details

Sustainability / Certifications / Approvals

ENVIRONMENTAL INFORMATION

| LEED® EQc 4.1 (100 g/L limit) | SCAQMD, Rule 1168 (100 g/L limit) | BAAQMD, Reg. 8, Rule 51 (120 g/L limit) |

| passes | passes | passes |

APPROVALS / STANDARDS

- Independently tested to -STC 62 (ASTM E-90) (6 in. (168 mm) concrete slab, 5/8 in. (19 mm) suspended gypsum ceiling)

- Reduction of Impact Sound Δ IIC = 21 (ASTM E-2179)

Sag Flow

Consistency: Spreads very easily

Ambient Air Temperature

Room temperature between 60 °F (15 °C) and 90 °F (35 °C). For ambient temperatures the standard construction rules are relevant. Follow all wood floor manufacturers’ acclimation and room temperature requirements.

Relative Air Humidity

Between 40 % and 70 % during installation is best for adhesive. See wood floor manufacturer for wood requirements.

Substrate Temperature

During laying and until SikaBond®-T21 has fully cured, substrate temperature should be greater than 60 °F (15 °C) and in case of radiant floor heating, less than 70 °F (20 °C). For substrate temperatures, the standard construction rules are relevant.

Substrate Moisture Content

For use as an adhesive and moisture membrane:

Concrete must be visibly dry. Inspect for any wetness at base of drywall or visible signs of moisture on concrete. Concrete and cement-based underlayments must be fully cured and free of any hydrostatic and/ or moisture problems. When properly applied in accordance with Sika® guidelines, SikaBond®-T21 provides unlimited moisture vapor protection.

For use as an adhesive only:

SikaBond®-T21 is not affected by moisture or vapor transmission. For protection of the wood, follow the wood floor manufacturer’s requirements for subfloor moisture. If substrate is not acceptable, use SikaBond®-T21 at recommended coverage rate as All-in-One or Sika® MB. See Technical Data Sheet for proper instruction.

Curing Rate

Floor may accept light foot traffic after:

- at 45–50 SF/gal (P5 trowel): after 6–8 h

- at 30–35 SF/gal (SC+MB trowel): after 12 h

(depending on climatic conditions and adhesive layer thickness)

Floor can be sanded after 18 hours

Skin Time / Laying Time

| ~ 45–60 minutes | (at 73 °F (23 °C) and 50 % R.H.) |

SEE ALL INSTALLATION MATERIALS

Visit Our Phoenix Showroom!