Description

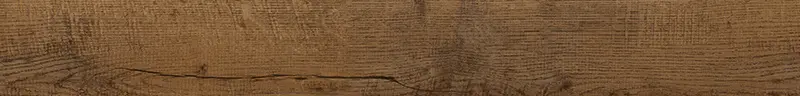

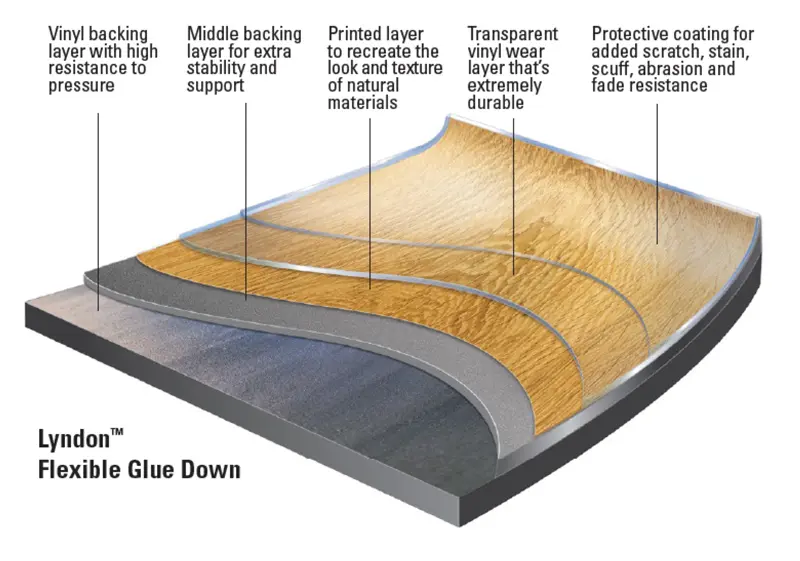

Nova Lyndon Collection – Williamsburg Glue Down Vinyl Flooring

Types of Vinyl Flooring

The original sheet vinyl flooring is similar to linoleum, which comes in rolls that you glue to the subfloor with mastic, but more recent products are thicker and lay flat without glue. You typically attach them to the floor with double-faced acrylic tape. Vinyl tiles come with or without a glued backing; if you choose a product that isn’t already glued, you must spread the glue yourself. Vinyl planks are designed to float over the subfloor like laminate flooring boards. Some products are constructed with locking systems, like laminate boards, while others have glue strips to hold them together.

If you want a permanent floor covering that won’t lift and can withstand impacts, scratches and spills, you should glue down vinyl sheet or tile flooring. When glued vinyl wears out, you can usually lay a new floor directly over it. Glue-down sheets and tiles can last as long as 20 years, however, so you shouldn’t need to do that any time soon. Most people choose glue-down vinyl over the loose-lay varieties for these reasons and for another important one: It’s one of the least expensive flooring options available.

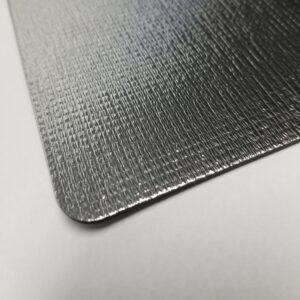

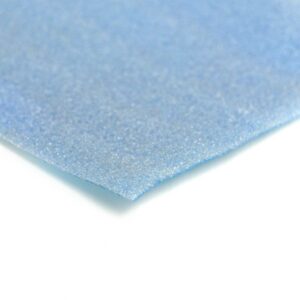

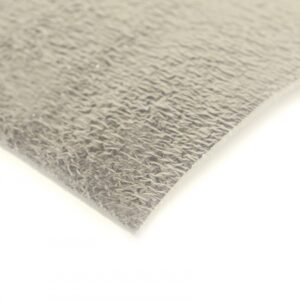

The glue down installation method involves the use of an adhesive to adhere your dry back luxury vinyl flooring to its base. Using an adhesive creates dimensional stability that ensures the flooring maintains its natural characteristics. The glue down method involves two distinct types of adhesives: hard set and pressure sensitive.

• Hard Set — Similar to a broadloom carpet adhesive, a hard set adhesive spreads along the subfloor — which in turn holds the vinyl flooring firmly in place. This is especially important for environments within the healthcare or retail industries that experience heavy rolling traffic such as wheelchairs and gurneys or shopping carts and dollies. As a relatively new adhesive product to the luxury vinyl flooring market, hard set adhesive allows your glue down flooring to absorb a heavy point load, which means furniture and fixtures are far less likely to leave noticeable indentations when removed. Hard set is designed for sheet vinyl, but also works well with vinyl tile and plank.

• Pressure sensitive — As the longtime industry standard, pressure sensitive adhesive allows for an installation process that makes your flooring sturdy, yet easier to replace. Pressure sensitive adhesive is especially suited for the retail and hospitality industries, or those that tend to change up their brand on a continual basis. Pressure sensitive adhesive is ideal for vinyl tile and plank flooring.

The Loose-Lay Alternative

Loose-lay vinyl flooring products — often referred to as “floating” floors — generally offer a more cushioned feeling and more elegant appearance than glue-down ones. The thicker texture of loose-lay sheets helps them lay flat, gives them slightly more insulation value and makes them easier to walk on. Vinyl planks can be as much as 3/8 inches thick, which is as thick as laminate flooring boards, and the hefty construction allows for textured patterns that resemble real wood and tile. Loose-lay products are designed for easy installation, so you can save contractors’ fees by laying the floor yourself.

Subfloor Considerations

All other factors aside, the choice between loose-lay and glue-down vinyl flooring may boil down to the characteristics of the subfloor. Installing loose-lay sheeting with double-faced tape isn’t recommended in bathrooms or on large floors that require more than one seam. Moreover, both tape and glue aren’t recommended on a high-moisture subfloor, such as a below-grade concrete pad, which is instead a good candidate for a vinyl plank floor. The substrate for any type of vinyl flooring should be clean and flat, but this requirement is more important for glue-down floors, which tend to reveal even small imperfections in the subfloor.